Guide to Wire Rope

MENU

- Structural Wire Rope Applications

- Computer-Assisted Design and Detailing

- High Strength Structural Strand

- Custom Finishes

- Pre-stretching

- Striping

- Measuring Wire Rope

- Corrosion Protection

- End Terminations

- Attaching Sockets

- Proof loading

- Order Specifications

- Wire Rope Selection

- Rotation-Resistant Ropes

- Specialized Wire Rope

- Wire Rope Handling and Installation

- Standard Operating Practices

- Wire Rope Inspection

- Technical Info & Specifications

Rotation-Resistant Ropes

In certain instances the use of rotation-resistant wire rope is necessary to provide rotational stability to the lifted load. In general, the use of these wire ropes is limited to those situations where it is impractical to:

- Use a tag line

- Relocate rope dead end

- Increase sheave sizes

- Eliminate “odd-part” reeving

- Significantly reduce rope loading and rope fall length

Rotation-resistant wire ropes have less of a tendency to unlay when loaded than do conventional wire ropes. This results in improved rotational stability to the lifted load. Rotation-resistant wire ropes are designed in such a way that the rotational force of the outer strands is partially counteracted by the rotational force of the inner strands or core when the rope is subjected to a load.

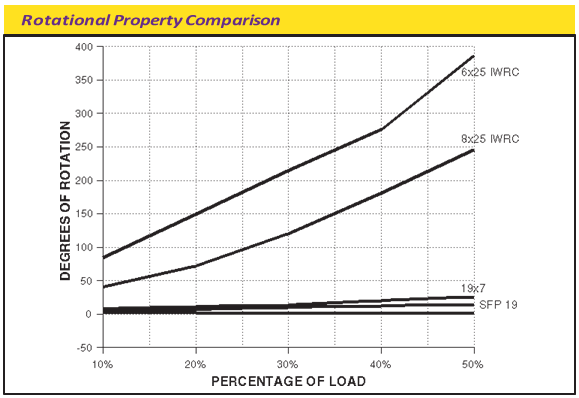

The chart compares the rotational properties of rotation-resistant ropes with a standard 6x25 wire rope. The rotation-resistant ropes far surpass the rotational stability of a conventional 6x25 IWRC wire rope on both short and long falls.

Safety Design Factors

ASME B30.5 specifies that rotation-resistant ropes have a safety design factor of five or greater. The required strength design factor of rotation-resistant rope becomes very important from the standpoint of maintaining the inherent low rotation of the rope and eliminating any tendency to overload the inner core, thereby causing a reduction in rope strength.

Handling and Installation

Precautions should be followed when using rotation-resistant wire rope. The rope ends must be properly seized and secured to prevent unlaying of the strands.

Attachment of end fittings must be done with care to prevent kinking or unlaying of rope, which harms the rotational balance of the rope.

Due to the opposite lay direction of the inner core and outer strand layers in rotation-resistant ropes, care should be taken to avoid shock loading. Shock loading will result in distortion of the rope structure, causing bird-caging, core protrusion, etc. Due to the potential for complete rope failure, shock loaded wire ropes must be immediately removed from service.

Swivels

Operation of 8x25, 19x7 and SPF 19 rotation-resistant wire ropes with a swivel is not recommended. The use of a swivel allows the inner core to twist tighter, resulting in a significant reduction in rope strength, possibly leading to premature rope failure. A swivel may be used as a temporary device only during the initial installation period to help eliminate any installation-induced twisting or cabling.

The swivel must be removed from the reeving after rope installation is completed and before the crane begins operation. A swivel may be used with some rotation resistant ropes, always confirm with the manufacturer.