Guide to Wire Rope

MENU

- Structural Wire Rope Applications

- Computer-Assisted Design and Detailing

- High Strength Structural Strand

- Custom Finishes

- Pre-stretching

- Striping

- Measuring Wire Rope

- Corrosion Protection

- End Terminations

- Attaching Sockets

- Proof loading

- Order Specifications

- Wire Rope Selection

- Rotation-Resistant Ropes

- Specialized Wire Rope

- Wire Rope Handling and Installation

- Standard Operating Practices

- Wire Rope Inspection

- Technical Info & Specifications

Measuring Wire Rope Diameter

To provide the necessary length tolerances specified by our customers, our measuring techniques include:

- Measuring strand and rope under prescribed tension using a calibrated, certified and tensioned steel tape

- Use of predetermined reference marks and a fixed gauge for accurate socket positioning

With these measuring practices, tolerances of +/-1/8” can be maintained for most assembly lengths. More stringent tolerances can be furnished upon request.

Rope diameter is specified by the user and is generally given in the equipment manufacturer’s instruction manual accompanying the machine on which the rope is to be used.

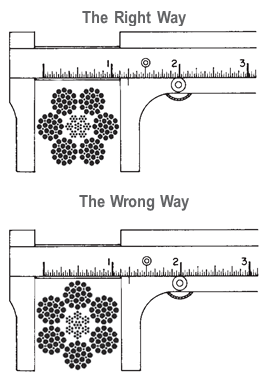

Rope diameters are determined by measuring the circle that just touches the extreme outer limits of the strands— that is, the greatest dimension that can be measured with a pair of parallel-jawed calipers or machinist’s caliper square. A mistake could be made by measuring the smaller dimension.