Hoisting and Rigging Standard

Operator Training/Qualification

Operators of mobile cranes shall be trained and qualified as required in Chapter 6, “Personnel Qualification and Training.”

Load Limits

- Since the load rating for mobile cranes may be based on stability and hydraulic or structural competence, load ratings established by the manufacturers shall not be exceeded in operational application

- No crane shall be loaded beyond its rated capacity, except for load test purposes as described in “Testing”

- When loads are to be handled that are limited by hydraulic or structural competence rather than by stability, the appointed person shall ensure that the weight of a load approaching rated capacity has been determined within -10 percent, +0 percent before it is lifted

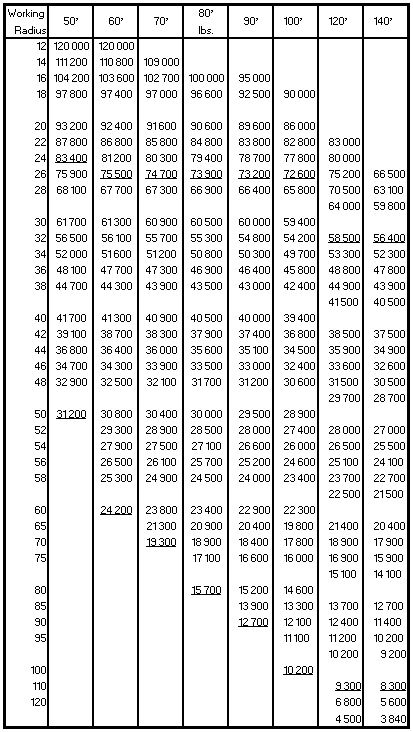

Load Rating Chart

- Durable rating chart(s) with legible letters and figures shall be provided with each crane and attached in a location accessible to the operator while at the controls. The data and information to be provided on these charts shall include, but not be limited to, the following:

- A full and complete range of manufacturer’s crane load ratings at all stated operating radii, boom angles, work areas, and all stated boom lengths and configurations, jib lengths and angles (or offset), as well as alternate ratings for use and non-use of optional equipment on the crane, such as outriggers and extra counterweights, that affect ratings

- A work area chart for which capacities are listed in the load rating chart

- Where ratings are limited by structural, hydraulic, or factors other than stability, the limitations shall be shown and emphasized on the rating charts

- In areas where no load is to be handled, the work area figure and load rating chart shall state that information

- Recommended reeving for the hoist lines shall be shown

- In addition to the data required on the load rating chart, the following information shall be shown either on the rating chart or in the operating manual:

- Recommended parts of the hoist reeving, and size and type of rope for various crane load

- Recommended boom hoist reeving diagram, where applicable; size, type, and length of rope

- Tire pressure, where applicable

- Cautionary or warning notes relative to limitations on equipment and operating procedures, including indication of the least stable direction

- Position of the gantry and requirements for intermediate boom suspension, where applicable

- Instructions for boom erection and conditions under which the boom, or boom and jib combinations, may be raised or lowered

- Whether the hoist-holding mechanism is automatically controlled or manually controlled, whether free-fall is available, and whether any combination of those exists

- The maximum telescopic travel length of each boom telescopic section

- Whether sections are telescoped with power or manually

NOTES:

- Above ratings are maximum recommended working loads. Loads between sold lines are computed at 75% of tipping load across treads; with machine on firm, level ground. Loads outside solid lines are limited by strength of boom

- For booms 80 ft and longer, use cambered center section; for booms 100 ft and longer, use deep section inserts

- The sequence and procedure for extending and retracting the telescopic boom section

- Maximum loads permitted during the actual boom-extending operation and any limiting conditions or cautions

- Hydraulic relief valve settings specified by the manufacturer

Load Hoist Brakes

When power-operated brakes that have no continuous mechanical linkage between the actuating and braking means are used, an automatic means shall be provided to set the brake to prevent the load from falling in event of loss of brake-actuating power.

Power-Controlled Lowering

A power-controlled lowering system shall be provided and shall be capable of handling rated loads and speeds as specified by the manufacturer of the crane.

Booms

- Booms, boom sections, and jibs shall be clearly identified and shall be used only for the purpose recommended by the manufacturer

- Lattice booms shall meet the performance requirements of SAE J987, “Crane Structure, Method of Test” (see Chapter 17, “References”)

Counterweight

- Cranes shall not be operated without the ballast or counterweight being in place as specified by the crane manufacturer. Under specific conditions, such as during crane assembly, unusual boom configurations, etc., the crane manufacturer’s recommendations for the amount of ballast or counterweight shall be adhered to

- Ballast or counterweight as specified by the manufacturer shall not be exceeded

Rerating

- Cranes may be modified or rerated providing such modifications are analyzed thoroughly by a qualified engineer or manufacturer of cranes. Such action must be approved by the cognizant safety organization

- When rerated, crawler, truck, and wheel-mounted cranes shall be tested in accordance with SAE J765, “Crane Load Stability Test Code”

- A rerating test report shall be readily available

- No cranes shall be rerated in excess of the manufacturer’s original load ratings

Maintenance History

The maintenance history of the crane shall be retained throughout it service life

Design Standards

- Structural, mechanical, and electrical components of the crane design shall meet accepted crane design standards, such as PCSA-4, “Mobile Power Crane and Excavator Standards and Hydraulic Crane Standards”

- The safety features and operation shall conform, at a minimum, to the provisions of ASME B30.5, “Mobile and Locomotive Cranes”