Hoisting and Rigging Standard

Operations

- The following shall apply to all personnel involved in mobile crane operation

- At the initial stage of the planning process, an appointed person shall classify each lift into one of the DOE-specified lift categories (ordinary, critical, or pre-engineered production)

Conduct of Operator

- Cranes shall only be operated by personnel qualified per Chapter 6 of this Standard for the type of crane being operated

- Do not engage in any practice that will divert your attention while operating the crane

- Keep the operating area free of water, snow, ice, oil, and debris that could cause your hands or feet to slip from the controls

- Keep the operating cab windshields clean and free of anything that obstructs vision. Replace broken windows

- Ensure proper functioning of tires, horn, lights, battery, controller, lift system (including load-engaging means, chains, hoist rope, and limit switches), brakes, and steering mechanisms. If at any time a lifting device is found to be in need of repair, is defective, or is in any way unsafe, report it immediately to the designated authority and take the unit out of service until it has been restored to safe-operating condition or a determination has been made by the responsible manager that the deficiency will not adversely affect the safe operation of the unit

- When two or more cranes are used to lift one load, one designated person shall be responsible for the operation. That person shall analyze the operation and instruct all personnel involved in the proper positioning, rigging of the load, and the movements to be made. That person shall also determine the necessity to reduce crane ratings, position of load, boom location, ground support, and speed of movement

- Determine that no one is working on the crane or is close to it before starting the engine or beginning to operate the crane

- Barricade accessible areas within the swing radius of the rear of the rotating superstructure of the crane to prevent anyone from being struck or crushed by the crane

- Do not hoist two or more separately rigged loads in one lift, even though the combined load is within the crane’s rated capacity. Refer to Section 15.5.8 for the exception granted for steel erection in construction

- When fueling the crane, stop the engine(s) and ensure that smoking or open flames are not permitted within 25 ft of the fueling area

- Ensure that a 10BC or larger fire extinguisher is installed at all operator stations. Fire extinguishers shall be maintained in a serviceable condition

- Do not store gasoline, acids, caustics, or cleaning solvents that emit toxic fumes in operating cabs. Store fuel in safety cans in safe locations

- Ensure that alternate egress routes are not locked on mobile units with operating enclosures

- Position the crane on a solid and level footing. It may be necessary in certain situations to use heavy timber mats to build a good working foundation

- When swinging the crane, watch out for centrifugal force. Swing the crane slowly to avoid an outward swing of the load. Attach a tag-line to the load if necessary to control the swing

- Watch for boom kickback. Never operate with the boom at a higher angle than shown on the capacity charts

- Use extreme caution when operating the crane near workers in elevated areas

- Use power lowering when lowering loads. When lowering heavy loads, keep the hoist brake as reserve. Use a safety pawl on the boom-hoist drum when not lowering

- Avoid two-blocking, caused when the hook block makes contact with boom-point sheaves. A continuing pull on the hoist lines can break the rope or pull the boom back over the cab on some types of booms. On hydraulically telescoping booms, be sure to play out the hoist line when extending and spool in the hoist line when retracting

- Lock carrier air brakes ON when operating, and check the pressure of the air brakes frequently

- Watch out for the carrier-cab on truck mounted units when swinging the boom. Keep boom high enough to swing clear of cab

- In the absence of crane manufacturer’s instructions regarding maximum wind speeds for operation, operations undertaken at wind speeds in excess of 25 mph should be evaluated by a qualified person to determine if the size, shape and weight of the load can be safely lifted

- When a crane is to be operated at a fixed radius, the boom-hoist pawl or other positive locking device shall be engaged

- On truck-mounted cranes, no loads shall be lifted over the front area, except as approved by the crane manufacturer

- Crane cabs, necessary clothing and personal belongings shall not interfere with access or operations

- Tools, oil cans, waste, extra fuses, and other necessary articles shall be stored in the tool box, and shall not be permitted to lie loose in or about the cab

Traveling the Machine

When traveling the machine:

- Secure the boom and book block

- Check bridges before crossing; make sure they will support the weight of the machine

- Check river depths before fording

- Check clearances under overpasses, overhead lines, or any overhead obstruction; when side clearances are tight, install a barrier or post a lookout, and make certain there is sufficient clearance for tail swing

- When traveling with a load, snub the load to prevent swaying if possible; never travel with near-capacity loads

- Never travel a rubber-tired unit with a load over the side

- On soft surfaces, always move with the load behind; it helps to raise the leading end of the crawlers, and makes traveling safer

- Always set swing brakes when the unit is idle or holding loads for a period of time, especially on slopes; if swinging during travel is necessary, engage swing-jaw clutch before releasing brakes

- Never back up until it is determined that everyone is clear of the machine

- Position the boom in the direction of travel for long moves

- Block treads when moving uphill; be sure they are blocked to prevent downhill movement before shifting steering clutches

- Lock the turntable before traveling on a highway. Use a house lock or swing brake, and lower boom into the rack to prevent swing

- When loading machine on the trailer, always use a ramp; if a ramp is not available use blocking to build one

Making Adjustments or Repairs

- When making adjustments or repairs:

- Stop the machine

- Lower the boom or secure it against dropping

- Neutralize all controls

- Lock starter and remove ignition key to make the machine inoperative

- Display proper warning signs on controls of machine

- Keep hands, feet, and clothing away from gears, ropes, drums, and sheaves

- Never put hands on wire rope when climbing to the top of the cab

- Use a bar or stick to guide wire rope onto drums

- Keep hands well away from the fan drive while engine is running

- Safeguard the crane oiler; do not resume operation until a positive ALL CLEAR signal has been given

- Replace all guards and shields before resuming operation

- Place blocking or other adequate supports under the boom before beginning boom disassembly operations. Never stand under or on the boom during this work

- Before disconnecting oil lines, if machine has hydraulic controls, be sure to place boom on the ground or in the boom rest; then move the pedals and control levers to equalize pressures within the cylinders. Always release any air supercharge on the hydraulic reservoir and shut off the engine (or declutch pumps) before disconnecting oil lines

- Do not reach into hydraulic-boom holes unless the sections are securely anchored together

Ensuring Stability

- Know the rated capacity of the crane and the weight of the load. A safe lift depends on many factors including boom length, boom angle, and load radius. Follow these requirements to avoid buckling the boom or tipping:

- Know the radius of the load; the radius is measured from center of rotation, not from the boom foot pin

- Always operate within the rated capacity of the machine

- The gross capacity includes weight of hook, block, and any material-handling devices, (i.e., slings, concrete bucket, magnet lifter, etc.); subtract the weight of all these to find the true weight (net capacity) the crane can handle safely

- Ratings are based on operating the machine on firm, level ground; outriggers should be properly extended and lowered before operation

- Avoid fast swings, hoists, or sudden braking; these can cause overloads

- Do not handle large, heavy loads in strong winds; the wind can catch the load and create an unstable condition

- Test stability before lifting heavy loads. Check outrigger footing. Lift load slightly off the ground and stop. Check the machine for movement ad check to be sure the brakes hold with the load elevated

- Never use machine stability to determine capacity

- If there are any indications of tipping, the machine is already overloaded for that working radius.

- Do not back crane away from the load while carrying a maximum load; this may cause the crane to tip.

- Always use outriggers when making lifts (with pick-and-carry units), and never lift a load forward of the front outriggers, unless allowed on manufacturer’s load chart

- Lower outrigger jacks until the tires clear the ground, and level the unit to reach the machine’s full capacity. Recheck and, if necessary, reset outriggers between heavy lifts

- Always fully extend outrigger beams unless otherwise specified on the manufacturer’s load charts for the crane

Further Safety Considerations

- Make only vertical lifts; never pull the load sideways

- Keep speed slow in lifting and lowering loads

- Swing carefully and slowly, and avoid boom or jib “whipping”; check counterbalance clearance

- Do not let the load strike the boom or outriggers

- Allow maximum clearance between the hook block and boom-point sheaves

- Keep near-capacity loads as close to the ground as possible

- Avoid hitting anything with the boom; an engineering analysis shall be made before putting the crane back in service if this occurs

Operating Near Power Lines and Transmitter Towers

It is recognized that operating mobile cranes where they can become electrified from electric power lines is an extremely hazardous practice. It is advisable to perform the work so there is no possibility of the crane, load line, or load becoming a conductive path.

The following steps shall be taken to minimize the hazard of electrocution or serious injury as a result of contact between the energized power lines and the crane, load line, or load:

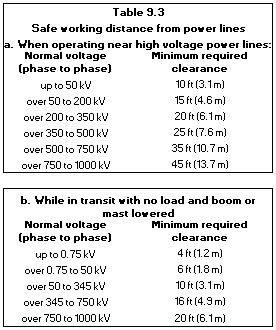

- The (electric) Power Marketing Administrations in DOE may deviate from the requirements of Table 9-3, providing the work is done according to line management approved procedures that do not conflict with statutory or approved variances from these regulations

- Any overhead wire shall be considered to be an energized line unless and until the person owning the line or the electrical utility authorities indicate that it is not an energized line

- Durable signs shall be installed at the operator’s station and on the outside of the crane, warning that electrocution or serious bodily injury may occur unless a minimum clearance of 10 ft (3.1m) is maintained between the crane or the load being handled and energized power lines. Greater clearances are required because of higher voltage as stated in Table 9-3. These signs shall be revised, but not removed when a local jurisdiction requires greater clearances

- Exercise caution when working near overhead lines having long spans as they tend to move laterally or vertically due to the wind, which could cause them to breach the safety zone

- Cranes shall not be used to handle materials stored under electric power lines unless any combination of the boom, load, load line, or machine component cannot enter the prohibited zone

- Crane operators shall not rely on the coverings of wires for their protection

Crane Operation Near De-energized and Grounded Electric Power Lines

This is the preferred condition under which the operation can be performed safely. The hazard of injury or death due to electrocution has been removed. The following steps shall be taken to assure de-energization of the power lines has occurred:

- The power company or owner of the power lines shall de-energize the lines

- The lines shall be visibly grounded to avoid electrical feedback and appropriately marked at the job-site location

- A qualified representative of the owner of the lines or a designated representative of the electrical utility shall be on site to verify that steps (a) and (b) have been completed and that the lines are not energized

Power Lines Energized, Crane Operating Less than Erected/Fully Extended Boom Length away from the Prohibited Zone

- An on-site meeting between project management and a qualified representative of the owner of the lines or a designated representative of the electrical utility shall take place to establish the procedures to safely complete the operations

- The specified clearance between the power lines and the crane, load line, and load shall be maintained at all times as specified in Table 9-3

- Load control, when required, shall utilize tag lines of a non-conductive type

- A designated signaler, whose sole responsibility is to verify that the required clearance is maintained, shall be in constant contact with the crane operator

- No one shall be permitted to touch the crane or the load unless the designated signaler indicates it is safe to do so

- Operation of boom and load over electric power lines is extremely dangerous, due to perception of distance and multiple contact points as viewed from the position of the operator and/or position of the designated signaler. The operator should avoid operating the crane, with or without a load, in this area

- The horizontal and vertical distance of movement of long span lines due to the wind shall be added to the minimum clearance distance as specified in Table 9-3. A qualified representative of the owner of the lines or a designated representative of the electrical utility shall be consulted for specific distances

- Devices such as ribbons, balls, etc, should be attached by a qualified person to the power lines to improve visibility, or equivalent means employed to aid in location of the prohibited zone

Crane Operations are Within the Prohibited Zone and the Power Lines are Energized

- Before such operations take place, a qualified person together with a qualified representative of the utility or an engineer qualified in power line transmission shall after visiting the site, determine if this is the most feasible way to complete the operation, and set minimum required clearances and procedures for safe operations. These operations shall be under their supervision. The following guidelines should be required:

- Crane/load grounded to a neutral line by the utility

- Electrical system protective devices that automatically re-energize the circuit after a power line contact occurrence should be blocked or disengaged to inhibit this function

- Insulated barriers, which are not a part of nor an attachment to the crane and which will not allow contact between the energized electric power lines and the crane, load lines, or load.

- Non-conductive barricades to restrict access to the crane work area

- Load control, when required, shall utilize tag lines of a non-conductive type

- A designated signaler, whose sole responsibility is to verify that the clearances established are maintained, shall be in constant contact with the crane operator

- The person responsible for the operation shall alert and warn the crane operator and all persons working around or near the crane about hazard of electrocution or serious injury and instruct them on how to avoid the hazard

- All non-essential personnel shall be removed from the crane work area.

- No one shall be permitted to touch the crane or the load unless the signaler indicates it is safe to do so

Crane in Transit With No Load and Boom Lowered

- Cranes in transit with no load and boom lowered shall maintain clearance as specified in Table 9-3

- A designated signaler shall be assigned to observe the clearance and give warning before the crane approaches the above limits

- When planning transit of the crane, the effect of speed and terrain on the boom and crane movement shall be considered

Crane Operation Near Transmitter Towers

- Prior to work near transmitter towers where an electrical charge can be induced in the equipment or materials being handled, the transmitter shall be de-energized or tests shall be made to determine if electrical charge is induced on the crane. The following precautions shall be taken when necessary to dissipate induced voltages:

- The equipment shall be provided with an electrical ground directly to the upper rotating structure supporting the boom

- Ground jumper cables shall be attached to materials being handled by boom equipment when electrical charge is induced while working near energized transmitters; crews shall be provided with non-conductive poles having large alligator clips or other similar protection to attach the ground cable to the load

- Combustible and Flammable materials shall be removed from the immediate area prior to operations

Hoist Limit Switch

Switches, if supplied, without a load on the hook at the beginning of each work shift or the first time the crane is used that shift. Inch each motion into its limit switch to ensure that two-blocking does not occur during the test. If a lift is in progress during a shift change, this testing requirement is considered to have been satisfied for the completion of that lift. However, test the limit switch again before the next lift.

Standard Hand Signals

The standard hand signals for DOE use shall be as specified in the latest edition of the ASME B30 standards for the particular type of crane or hoist being used, per below directionals.

Hoist – With forearm vertical, forefinger pointing up, move hand in small horizontal circles

Lower – With arm extended downward, forefinger pointing down, move hand in small horizontal circles

Use Main Hoist – Tap fist on head, then use regular signals

Use Whipline (auxiliary hoist) – Tap elbow with one hand, then use regular signals

Raise Boom – Extend arm, fingers closed, thumb pointing upward

Lower Boom – Extend arm, fingers closed, thumb pointing downward

Move Slowly – Use one hand to give any motion signal and place other hand motionless above the hand giving the motion signal (hoist slowly)

Raise the Boom and Lower the Load – With arm extended, thumb pointing up, flex fingers in and out as lone as load movement is desired

Lower the Boom and Raise the Load – With arm extended, thumb pointing down, flex fingers in and out as long as load movement is desired

Swing – Extend arm, point with finger in direction of swing of boom

Stop – Extend arm, palm down; move arm back and forth horizontally

Emergency Stop – Both arms extended, palms down, move arms back and forth horizontally

Travel – Extend arm forward, hand open and slightly raised; make pushing motion in direction of travel

Dog Everything – Clasp hands in front of body

Travel (both tracks) – Use both fists in front of body, making a circular motion about each other, indicating direction of travel, forward or backward (for land cranes only).

Travel (one side track) – Lock the track on side indicated by raised fist. Travel opposite track indicated by circular motion of other fist, rotated vertically in front of body (for land cranes only)

Extend Boom (telescoping booms) – Hold both fists in front of body, thumbs pointing outward

Retract Boom (telescoping booms) – Hold both fists in front of body, thumbs pointing toward each other

Extend Boom (telescoping boom) – One-hand signal. Hold one fist in front of chest, thumb tapping chest

Retract Boom (telescoping boom) – One-hand signal. Hold one fist in front of chest, thumb pointing outward and heel of fist tapping chest

Identification of Signalers

- All personnel acting as signalers during crane operations shall be clearly identified to the crane operator. Options for improving signaler visibility include using an orange hardhat, orange gloves or an orange vest

- In those cases where the crane operator cannot see the signaler, a second person (relay signaler) shall be stationed where he or she can see both the signaler and the crane operator, and can relay the signals to the operator. The relay signaler shall also be clearly identified to the crane operator

- The operator shall obey signals only from the designated signaler. Obey a STOP signal no matter who gives it

Standard Voice Signals

- Prior to beginning lift operations using voice signals, the signals shall be discussed and agreed upon between the person-in-charge, the crane operator, the appointed signal person and the riggers

- Radios or equivalent shall be tested before lifting operations begin

- Prior to commencing a lift, the crane operator and the signal person shall contact and identify each other

- All directions given to the crane operator by the signal person shall be given from the crane operator’s direction perspective (e.g., right swing)

- Each series of voice signals shall contain three elements stated in the following order:

- Function and direction

- Distance and/or speed

- Function stop

Special Signals

For operations or crane attachments not covered by standard hand, voice or audible signals, additions to or modifications of the standard signal procedures may be required. In all such cases, the required special signals shall be agreed upon in advance by the manager, person-in charge, crane operator, signal person and riggers. These special signals shall not be in conflict with the standard signals.

Size of Load

The crane shall not be loaded beyond its rated capacity, except of authorized testing described under “Operational Tests.”

Attaching the Load

- Ensure that the hoist rope is free from kinks or twists. Do not wrap the hoist rope around the load

- Ensure that the load is attached to the load block hook by means of slings or other approved devices

- Ensure the load is well secured and properly balanced in the sling or lifting device before it is lifted more than a few inches

- Take care to make certain that the sling clears all obstacles

Moving the Load

- The appointed person directing the lift shall make certain that the load is well secured and properly balanced in the sling or lifting device before it is lifted more than a few inches

- Before starting to hoist, not the following conditions:

- Hoist rope shall not be kinked

- Multiple-part lines shall not be twisted around each other

- The hook shall be positioned above the center of gravity of the load in such a manner as to minimize swinging when the load is lifted.

- Following any slack-rope condition, it should be determined that the rope is properly seated on the drum and in the sheaves

- All personnel including the qualified rigger shall be clear of the load

- During hoisting, take care to ensure that:

- There is no sudden acceleration or deceleration of the moving load

- Load does not contact any obstructions. A “dry run” shall be conducted in areas where clearance is limited

- Cranes shall not be used for side pulls, except when specifically authorized by a designated person who has determined that the stability of the crane is not endangered and that various parts of the crane will not be over stressed

- Avoid carrying loads over people

- No hoisting, lowering, swinging, or traveling shall be done while anyone is on the load hook, except as noted in Chapter 4, “Lifting Personnel”

- Test the brakes each time a load approaching the rated capacity is handled by raising the load a few inches and applying the brakes

- Do not lower the load below the point where less than two full wraps of rope remain on the hoist drum

- Do not leave your position at the controls while the load is suspended, unless required to do so by an approved emergency procedure

- If the load must remain suspended for any considerable length of time, the operator shall hold the drum from rotating in the lowering direction by activating the positive controllable means of the operator’s station

- Work on suspended loads is prohibited under normal conditions. When the responsible manager decides that it is necessary to work on a suspended load, guidelines for ensuring safety of the work shall be established through consultation with the appropriate safety organization. Suspended loads that must be worked on shall be secured against unwanted movement

- Tag lines should be used as required to guide, snub, or otherwise control the load

Ordinary Lifts

- The requirements of all preceding paragraphs, “Operation,” (ordinary, critical or pre-engineered production) before the lift is planned

- Hoisting and rigging operations for ordinary lifts require a designated leader who shall be present at the lift site during the entire lifting operation. If the lift is being made by only one person, that person assumes all responsibilities of the designated leader

- Leadership designation may be by written instructions, specific verbal instructions for the particular job, or clearly defined responsibilities within the crew’s organizational structure.

- The designated leader’s responsibility shall include the following:

- Ensure that personnel involved understand how the lift is to be made

- Ensure that the weight of the load is determined, that proper equipment and accessories are selected, and that rated capacity is not exceeded

- Survey the lift site for hazardous/unsafe conditions

- Ensure that equipment is properly set up and positioned

- Ensure that a signaler is assigned, if required, and is identified to the operator

- Direct the lifting operation to ensure that the lift is completed safely and efficiently

- Stop the job when any potentially unsafe condition is recognized

- Direct operations if an accident or injury occurs

- The designated leader shall inspect all cranes to ensure that they are still within the inspection interval

- The designated leader shall inspect all lifting devices to ensure that the rated capacity of these items of equipment will not be exceeded

- The operator shall inspect for damage and defects in accordance with “Daily Preoperational Check” including observations during operation. A qualified person shall examine deficiencies and determine whether they constitute a hazard

- Check hoist-limit switches, if provided, according to “Hoist-Limit Switch”

- Ensure that basic operating instructions of power-operated equipment, together with charts, tables, or diagrams showing the rated capacity, boom angle, swing, and stability data are posted in convenient view of the operator

- Check load lines after strain is put on them but before the load is lifted clear of the ground; if load lines are not plumb, reposition the slings or equipment so that the lines are plumb before continuing

Critical Lifts

See Chapter 2, “Critical Lifts,” for critical-lift requirements.