Case Studies

Calling on the Experts

Profile

A global manufacturer of industrial lifting equipment.

Customer Challenge

When our customer needed fast turnaround on a 37-ton alloy swivel shank hook with a fabricated bearing retainer nut they called Assembly Specialty.

Assembly Specialty Solution

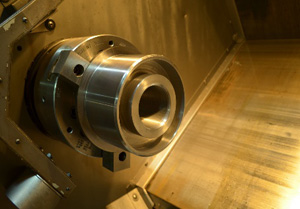

The hook shank was machined to the appropriate diameter and threaded with 3” – 8 UN 2B threads on one of our dozen computer controlled lathes. The bearing retaining nut was then cut from 7” diameter AISI 4130 alloy steel round stock and machined to accept a crane hook thrust bearing ring, then threaded to mate perfectly with the threads on the hook shank.

The finished hook assembly was picked up by the customer and delivered to the job site in less than two weeks.